Louie and I bought this sewing machine last night for The Sewing Machine Project. It is a Sears Kenmore Model 1303. (Or technically, 158.13032) Kenmore says it was built in 1969. They built things to last back then. We knew it had issues when we bought it, even though there was a sign on the cabinet which said ‘Tested’. Yup. Uh huh. That’s ok. We were up for a challenge!

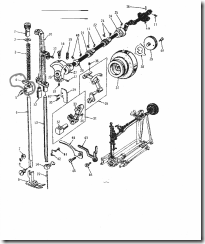

One problem it had that I was NOT aware of, was that the presser bar was STUCK in the UP position. That means that you cannot lower your presser foot, and if you can’t lower your presser foot, you can’t sew! If you look at the picture below, (you will have to enlarge it) you will see a part, which I have circled. That is the presser bar bracket. That bracket is attached to the presser bar, which holds your presser foot. When you lift the lever to raise and lower the presser bar, this bracket is what works with the presser lever to raise the bar and your presser foot from the feet dogs so you can get your fabric under and out of the machine. When the bar is stuck, nothing happens. In this case, the bar was UP, then it got stuck. This machine has been sitting around for decades, I am SURE. Unless the bar goes down, there will be no sewing.

The bar wouldn’t budge. The presser foot bracket is the part which is dark colored and has two screws going into it, just under the spring. It has a ‘leg’ on it, which sticks out the back of the machine, and the presser bar lifter pushes it up against the spring. But it just wouldn’t move…..

…so I tried to help it…(with a hammer and a screwdriver)…..OH NO! It broke! It’s made from cast metal.

Louie was at the ‘Y’ when I broke this part, so I moved on to the more obvious problem. The darn machine was STUCK too! It would move, but only with brute force! I turned and turned the hand wheel manually, and added oil to every place I could see had a joint and moved (or should move) and I put grease on the gears, and I checked for thread wrapped around the hand wheel (not the problem), and I just kept working it. If you look closely, you can see where the belt goes on to the motor. There is black thread wrapped around it. That really wasn’t a function problem though. I removed it.

When I felt I had oiled everything I could, I plugged it in and tried to see if I could get the motor to move the machine. I did see a little smoke, but you should have seen the black pieces of carbon and ‘whatever’ that flew out of the motor when I turned it on. I didn’t think to photograph that mess. I just kept manually turning the hand wheel, and then I would try to force the motor to do it for me. Eventually, the motor started turning things, and I just kept ‘flooring it’ with the foot controller, and FINALLY, whatever was binding, broke free, and this baby MOVES! Oh my Good Heavens! The motor is fine. I was just putting too much load on it in the beginning. (That is, after all the crap got blown out of it from sitting around for decades). It was also covered in gravel dust, or something.

So my sweet Louie went out to work when he got back from the ‘Y’ to braze this piece back together. He completely removed the presser bar. (For those wondering….the part is no longer available). I am learning so much about sewing machines by fixing them, and my hubby is learning more than he intended to, but that’s ok. We’re a team! We have never had a sewing machine this far apart before. I guess you have to start somewhere, right? What did we have to lose?

Louie returned with the piece brazed back together!

We won! It lives! It straight stitches, zigzags, and blind stitches. It also has forward and reverse on the stitch selector knob for making button holes. (Of course, I did have to buy a manual so I could figure everything out!) Isn’t the internet a wonderful thing?

It winds a beautiful bobbin!

Other than Louie taking a peek inside the motor and cleaning that up some, it is ready to go to The Sewing Machine Project!

I’m hoping everyone is having a wonderful weekend. We are going to a Gaither Homecoming Tour concert tonight with our friends Dave and Judy. It will be so much fun!

Be blessed!

Michelle

Enjoy the concert!! I continually love to read about your adventures fixing up the sewing machines!! I have to get a picture of the sewing machine here in our garage and send it to you; hubby thinks it is over 60 years old.

ReplyDeleteGood for you and Lou working together on these projects! Such a blessing indeed!

betty

Wow that was some stubborn machine. You are really the "sewing machine whisperer". Have fun at the concert.

ReplyDeleteYou both are miracle workers! Have fun at the concert!!!!

ReplyDeleteYea! A fix and a newly working machine that was ready for the trash. Great to save these machines.

ReplyDeleteYou have saved another machine! We need to come up with some official title for you - Queen of Machines or something? You are amazing!

ReplyDeleteOh my goodness you're going to have fun at that concert! Congratulations on getting the Kenmore to work - hard work always pays off. blessings, marlene

ReplyDeleteWhat a challenge but you guys do a wonderful job restoring old machines! Congrats!

ReplyDelete